Variable Capacitors: A Complete Guide

Release time : 2023-09-27

A variable capacitor is a capacitor whose power capacity can be adjusted within a certain range. It is widely used in electronic technology. This guide is designed to provide you with the ultimate guide to variable capacitors, allowing you to understand the basics, types, and applications of variable capacitors.

<>Catalog

Ⅰ.What is a variable capacitor?

Ⅱ.Classification of variable capacitors

Ⅲ.Variable capacitor principle

Ⅳ.Variable capacitor applications

4.1.Resonant circuit

4.2. Frequency selective oscillation

4.3.Tuning

4.4.Oscillator circuit frequency adjustment

4.5.Antenna matching

Ⅴ.Special form of mechanically variable capacitor

5.1.Bidirectional variable capacitor

5.2.Knob type variable capacitor

5.3.Press-type variable capacitor

5.4.Small summery

Ⅵ.There are two main variable capacitor type

6.1.Mechanical control capacitor

6.2.Types of mechanical control capacitors

Ⅶ.Electronically controlled capacitor

Ⅷ.FAQ

Ⅰ.What is a variable capacitor?

Figure1:Variable capacitor

Variable capacitor refers to a capacitor whose capacitance can be adjusted within a certain range. It is generally composed of two sets of pole pieces that are insulated from each other. Among them, a set of fixed pole pieces is called a fixed piece, and a movable set of pole pieces is called a moving piece. The capacitance can be changed accordingly by changing the relative effective area or the distance between the pole pieces. . Variable capacitors are often used in L/C circuits to set the resonant frequency, such as for tuning radios (hence sometimes called tuning capacitors or tuning capacitors), or as variable reactance, such as for impedance matching in antenna tuners.

Figure2:Variable Capacitor Symbol

Ⅱ.Classification of variable capacitors

According to the structure, variable capacitors can be divided into: fine-tuning variable capacitors, single variable capacitors, double variable capacitors and quadruple variable capacitors.

Ⅲ.Variable capacitor principle

A variable capacitor consists of two sets of metal sheets that are insulated from each other. The fixed set of the two sets of electrodes is the stator, and the rotating set is the moving piece. Air is used as the medium between the moving piece and the stator. When all the moving pieces of the air dielectric variable capacitor are rotated into the space between the fixed pieces, the capacitance is the largest; conversely, when all the moving pieces are rotated out of the space between the fixed pieces, the capacitance is the smallest.

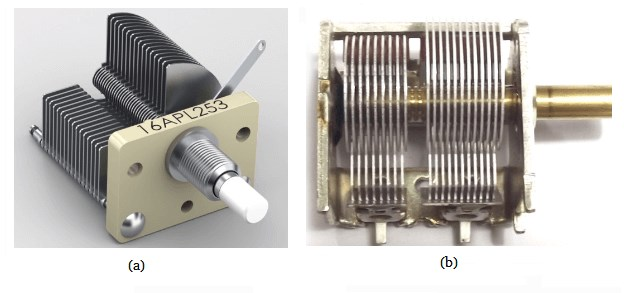

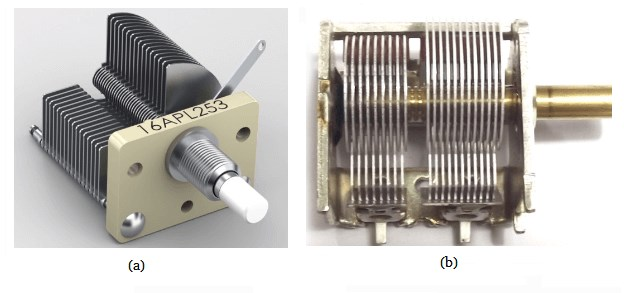

Figure 3.air variable capacitor

In practical applications, several moving pieces of variable capacitors can be installed on the same rotating shaft to form a coaxial variable capacitor (commonly known as double, triple, or even N-connected, etc.).

Figure 4. (a) air single-connected variable capacitors (b) air double-connected variable capacitors

Ⅳ.Variable capacitor applications

4.1.Resonant circuit

Figure 5.Resonant circuit

The LC resonant circuit can change the resonant frequency by changing the capacity of the variable capacitor C.The resonant frequency is inversely proportional to the square of the capacitance, and the calculation formula is as follows:

4.2. Frequency selective oscillation

The application of capacitors in oscillators can make the oscillation frequency continuously adjustable within a certain range. In the high-frequency signal generator circuit, by adjusting the unrequited love variable capacitor C, the output signal frequency can be changed as needed.

Figure 6.Frequency selective oscillation

4.3.Tuning

It is often used in the tuning circuit of radios to select radio stations. As shown in the figure, the following figure is a superheterodyne radio frequency conversion stage circuit. One of the double variable capacitors C1, C1a, is inserted into the antenna output loop, and the other C1b is connected to the local oscillation loop. The capacity of the two connected capacitors of C1 is adjusted to change synchronously. The receiving frequency can be changed. C2 and C3 are both fine-tuning capacitors, used for frequency calibration of the antenna input loop and the local oscillation loop respectively.

Figure7.Tuning

4.4.Oscillator circuit frequency adjustment

Adjustment of additional capacitance around the passive crystal oscillator, trimming capacitors are used to adjust the inherent error of the crystal oscillator. Generally used for: wireless electronic devices, wireless electronic door locks, watches, etc.

4.5.Antenna matching

Due to the skew and twist of the antenna itself, the inductance (L) will change. By adjusting the capacitance value (C) using a trimmer capacitor, the desired frequency can be adjusted. Generally used in: wireless communication equipment, mobile phones, RFID/NFC card readers, etc.

Ⅴ.Special form of mechanically variable capacitor

Special forms of mechanical variable capacitors refer to some uncommon or specially designed variable capacitors. Their structures and working principles are different from ordinary variable capacitors. For example:

5.1.Bidirectional variable capacitor

This type of variable capacitor has two rotating axes, which can simultaneously adjust the overlapping area of the two sets of moving pieces and fixed pieces, thereby realizing the adjustment of two independent capacitance values 1.

5.2.Knob type variable capacitor

This type of variable capacitor does not have a moving piece, but changes the distance between the fixed pieces by rotating a metal plate with grooves, thereby changing the capacitance value 2.

Sliding variable capacitor: This type of variable capacitor also does not have a moving piece. Instead, it changes the overlapping area with the fixed piece by sliding a metal plate, thereby changing the capacitance value 3.

5.3.Press-type variable capacitor

This type of variable capacitor uses the elasticity of the metal spring to change the distance between the pole pieces. When the spring is pressed, the capacitance value increases; when the spring is released, the capacitance value decreases by 4.

5.4.Small summery

These special forms of mechanically variable capacitors are usually used in some specific occasions or situations that require precise adjustment. Their advantages are simple structure, convenient operation, and low cost; their disadvantages are mechanical wear, short life, and poor stability.

Ⅵ.There are two main variable capacitor type

6.1.Mechanical control capacitor

A mechanically controlled capacitor is a capacitor whose capacitance value can be changed mechanically and is commonly used in circuits such as radio tuning, oscillation, and amplification. Its structure is generally composed of a set of fixed metal plates (fixed plates) and a set of rotatable or movable metal plates (moving plates). The capacitance value is changed by changing the overlapping area or distance between the two sets of metal plates.

6.2.Types of mechanical control capacitors

①Rotary variable capacitor: This is the most common type of mechanically controlled capacitor. Its moving piece is installed on a rotating shaft, and the overlapping area between the moving piece and the fixed piece is adjusted through the rotating shaft. Its advantages are simple structure, convenient adjustment, and wide capacitance range; its disadvantages are large size, mechanical wear, and temperature influence.

②Sliding variable capacitor: The moving piece of this mechanically controlled capacitor is a metal plate, which changes the overlapping area with the fixed piece by sliding. Its advantages are small size, compact structure, and flexible adjustment; its disadvantages are small capacitance range, poor contact, and being affected by dust.

③Press variable capacitor: This mechanically controlled capacitor uses the elasticity of the metal spring to change the distance between the pole pieces. When the spring is pressed, the capacitance value increases; when the spring is released, the capacitance value decreases. Its advantages are simple structure, convenient operation and fast response; its disadvantages are small capacitance range, poor stability and easy to be affected by external forces.

Ⅶ.Electronically controlled capacitor

An electronically controlled capacitor is a capacitor whose capacitance value can be controlled by external voltage or current. It is usually used in tuning, filtering, matching and other circuits. It comes in two main types: voltage controlled capacitor (VCC) and current controlled capacitor (ICC). Voltage-controlled capacitors utilize the nonlinear characteristics of the medium to cause the capacitance value to change as the applied voltage changes.

Current-controlled capacitors utilize the ferroelectric properties of the medium to cause the capacitance value to change as the applied current changes. The advantages of electronically controlled capacitors are that they can achieve characteristics such as no mechanical wear, no noise, fast response, and low power consumption.

Ⅷ.FAQ

Q1: What is a variable capacitor and how does it work?

A: A variable capacitor is a capacitor whose capacitance can be adjusted within a certain range. It works by changing the effective area or distance of the plates, or by changing the dielectric material between the plates.

Q2: What are the types of variable capacitors and what are their characteristics?

A: There are two main types of variable capacitors: mechanical variable capacitors and electrically controlled capacitors. Mechanical variable capacitors use movable plates or screws to change the capacitance, and they have low loss, high stability, long life, but large size. Electrically controlled capacitors use voltage or current to change the capacitance, and they have no mechanical wear, no noise, fast response, low power consumption, but high loss and low stability.

Q3: What are the applications of variable capacitors and what are their advantages?

A: Variable capacitors are widely used in radio frequency circuits, such as tuning, filtering, matching, oscillating, etc. They can adjust the resonance frequency, impedance, phase, or bandwidth of the circuits according to the needs. They also enable some novel technologies such as smart antennas, metamaterials, quantum computing, etc.

Q4: How to choose a suitable variable capacitor for a specific circuit or device?

A: There are several factors to consider when choosing a variable capacitor, such as the required capacitance range, voltage rating, quality factor, temperature coefficient, size, shape, packaging, etc. The choice depends on the design specifications and performance requirements of the circuit or device.

Q5: How to measure and test the capacitance and other parameters of a variable capacitor?

A: There are different methods and instruments to measure and test the capacitance and other parameters of a variable capacitor, such as using a multimeter, an LCR meter, an oscilloscope, a network analyzer, etc. The measurement and test procedures vary depending on the type and model of the variable capacitor and the instrument used.